Best Software Required To Setup CNC Machines

Setting Up CNC Machines (CNC Setup Sheets)

Set up a CNC machine involves a few key steps, such as setting up the workspace, installing the workpiece, choosing and loading tools, setting tool length offsets, and setting up the work coordinate system. Before starting, make sure the machine is turned on and the coolant system is working, and run a test to verify the program and ensure proper machine performance.

CNC Machine Setup Key Considerations

To set up the CNC machine, first clean the machine table and surrounding areas for a clear and organized workspace. Install the workpiece and securely assemble the workpiece in the appropriate workholding device (e.g., vise, chuck) and align it accurately using reference edges and faces.

Now, select the tools and select the correct cutting tools for the machining process, and load them into the tool changer or toolholders. To set tool length offsets, measure, and set tool length offsets using a tool presetter or manual measurement.

Then, define the "workpiece zero" to align the machine's reference point with the workpiece's coordinate system. As per the IQS Directory, check and replenish coolant levels and ensure proper lubrication of moving parts.

Load the CNC program onto the machine and run a test cycle to verify the program and machine settings before starting the actual machining work. During the machining process, monitor the machine's performance and make any necessary adjustments to feed rates, speeds, and other parameters.

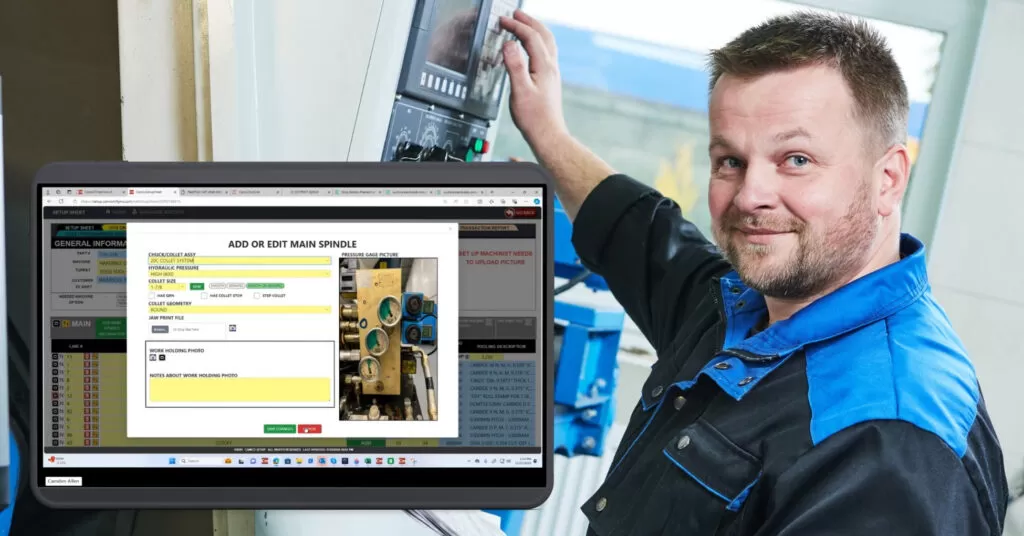

CNC Machine Setup Using Setup Sheets

CNC machine setup using setup sheets is the process to prepare the machine for a job, such as loading the program, and confirming accuracy before starting the manufacturing procedure. This process includes cleaning the machine, loading tools, setting tool offsets, installing workholding, setting part zero, and verifying the program.

Here's a more detailed breakdown:

Pre-Setup Preparation:

- Clean the machine: Remove any debris, chips, or coolant from previous operations.

- Tool selection and loading: Choose the appropriate tools for the job and load them into the tool changer or manual holders.

- Tool length and diameter offsets: Set the tool length offsets using a probe or manual measurement, and set tool diameters for cutter radius compensation.

- Warm-up the machine: Ensure the machine is warmed up to operating temperature.

Workpiece and Workholding:

- Install the workpiece: Secure the workpiece on the machine table using clamps, vises, or fixtures, ensuring it's aligned correctly.

- Set part zero: Define the zero point for the workpiece, which is the origin for the program's coordinate system.

Loading and Running the Program:

- Load the program: Transfer the G-code program from the computer to the CNC machine.

- Verify program settings: Check the program version, tool numbers, speeds, feeds, and any other relevant settings.

- Dry run (air cut): Run the program without the tool cutting the material to visually verify the toolpaths and offsets.

- Adjust settings: If necessary, adjust feeds, speeds, or offsets based on the dry run.

First Cut and Quality Check:

- Perform a test cut: Use scrap material for the first cut to verify the accuracy of the program and offsets.

- Measure and inspect: Measure the workpiece dimensions and tolerances to ensure they meet the requirements.

- Adjust if needed: If any discrepancies are found, adjust tool offsets or cutter compensation accordingly.

Ongoing Monitoring and Maintenance:

- Coolant and chip management: Ensure proper coolant flow and chip removal to prevent tool wear and overheating.

- Monitor the machine: Keep a close watch on the machine during the machining process to detect any issues.

Why Need Setup Sheets:

- Documentation: Setup sheets provide detailed instructions for setting up the machine for a specific part or operation.

- Tool information: They include information about tools, speeds, feeds, and other relevant parameters.

- Workholding details: They specify how the workpiece should be clamped and the location of part zero.

- Program information: They include the program file name, location, and version.

- Checklist: They may include a checklist to ensure that all steps of the setup process have been completed.

.png)